Real Time Production

Monitoring System

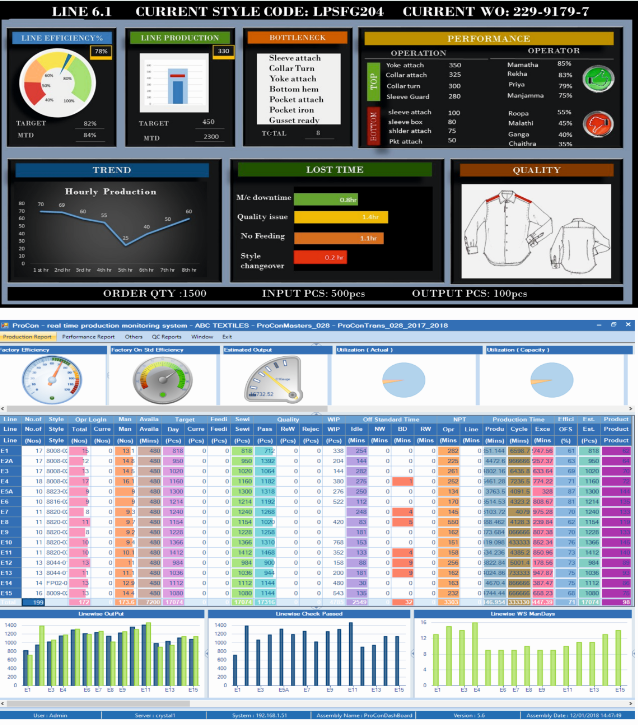

Prospice presents a real-time production monitoring system that is robust, state-of-the art revolutionary technology that promises to take the pain out of production management. Procon System collects production information in real-time and disseminate quickly and accurately to production management team to identify and react to the problems in the production line instantaneously.