ProSpice

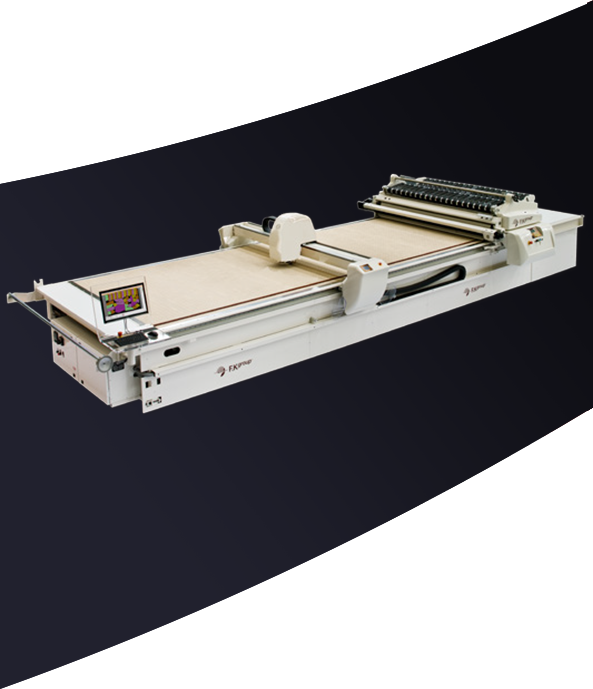

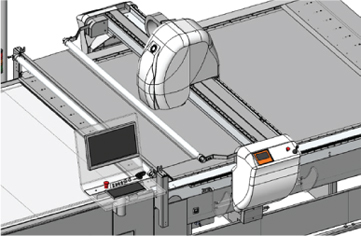

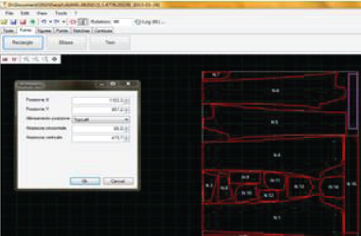

Cutting & Spreading

Cutting and Spreading Machines for all kinds of garment industry adjusted to our Client's needs. Top-quality machinery with proper consultancy and Maintenance Management means the right solution for your industrial growth.